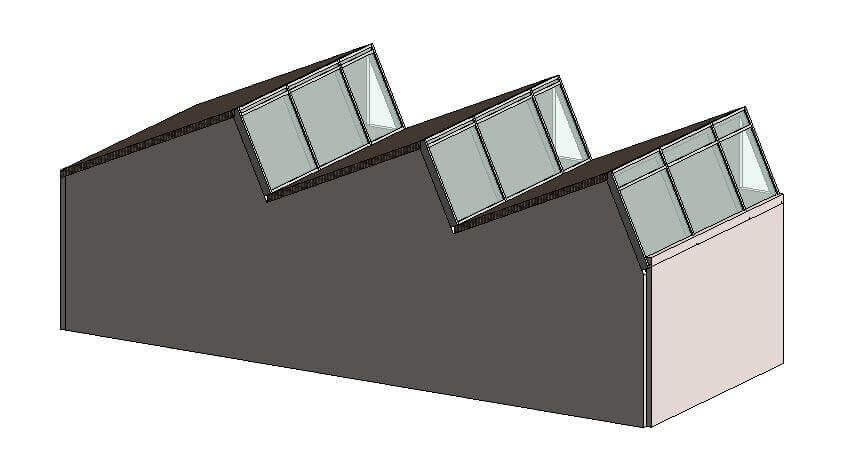

What is a Saw-Tooth Roof?

The saw-tooth roof is a unique style of roof construction. The profile of the roof style resembles a series of skillion roofs. The saw-tooth roof was common in ancient industrial buildings. The form is series of ridges and dual pitch which was designed to protect workers from direct sunlight.

The main reason behind the construction of saw-tooth roof was to increase the amount of light inside a room while reducing the effect of glare and excess heat. With electricity gaining status, saw-tooth roofs became less popular.

However, the migration of the world toward energy-saving machines and materials has seen saw-tooth roof becoming accepted. The roof style continues to go through innovations to make it a superior product for homes, offices, and industries. Cool roof and radiation barriers are some of the materials incorporated into the saw-tooth roof to improve its efficiency in cooling.

Construction of Saw-Tooth Roof

Saw-tooth roofs utilize the strength of wood, concrete, and metal in construction. Symmetry and uniformity are crucial factors in creations of saw-tooth roofs. The beams used in the development of the shelters have longer spans than any conventional roof. The dead load of the roof is larger than the live weight; therefore, the structural reinforcement required during construction is more significant. Many engineers use steel reinforcement for more substantial support. A series of metal trusses are used to support the hinged section of the roof.

Construction of the roof involves several ridges and valleys. They require a durable material like metal or slate to resist wear and tear. Materials like Asphalt shingles are weak and will need regular maintenance to uphold the structural integrity of the building.

Creation of the roof section occurs in broken parts, with each roof proper inclining about fifteen degrees. The transparent portions need inclination of sixty degrees.

Gutters fitted to sawtooth roofs should be strong since they hold large volumes of water which flow at high speeds. Box gutters installed to the saw-tooth roofs should undergo routine maintenance to prevent leaking and to sag. The drains are prone to carry leaves and dirt which cause a blockage in the gutters.

Maintenance of Saw-Tooth Roofs

Although metal used in saw-tooth roofs are durable, the design of the roof makes it prone to minor rusting because of trapped water. The Use of inappropriate material on saw-tooth roofs will cause failure because of the general weight of the roof. During maintenance, it is important to note the materials used to replace older ones.

Benefits of Saw-Tooth Roofs

Since they maximize the use of natural lighting, sawtooth roofs reduce the energy costs. In addition to the natural lighting; saw-tooth roofs are efficient in equal distribution of light while blocking direct exposure.

The high pitch used in the construction of the saw-tooth roof provides extra interior space due to the high ceilings. The high ceilings make room for a better circulation of air in the interior area. They also offer resistance to storms experienced with the Australian climate condition. The slope goes drainage of stormwater easy.