Roof Flashing – Keeping the Water Out

When installing a roof, it is not enough to simply throw up some framing and cover it with a waterproof membrane and roof tiles—there are plenty of problem spots where water can get in, such as the borders where the roof meets with other parts of the building. Naturally, you can’t leave these problem spots unattended, but thankfully, there is a way of handling this, and that way is flashing. But what is roof flashing?

Roof flashing is the process using various materials to seal the areas around a roof that may be liable to water ingress and is necessary to ensure water does not leak into the property. There are many different ways in which this kind of weakness can be found in a roof, as well as many different materials that can be used when flashing.

Why is Roof Flashing Necessary?

For people who know little about how roofs are constructed, it can be surprising to learn that flashing is needed. After all, roofs are made to keep water out, aren’t they? Why would you need additional treatment to keep water from getting in? The truth is, few things are as invasive as water. Over time, it can erode mountains, carve valleys, and if there is a way for it to get in through your roof, it undoubtedly will.

The main way this happens on a roof is via spots where water can pool. If water is kept moving, such as is the case with a pitched roof, it will take the path of least resistance. If it is allowed to settle in one place like the small valley created where a pitched roof meets a vertical surface, it will leak through any point of ingress it can, like seeping under the roof shingles.

Roof flashing prevents this by ensuring there are no points where water can pool and making sure that it always has a smooth path towards whatever drainage system is in place. One way to think of flashing is as reinforcement against water ingress.

How Does Flashing Work?

In the simplest sense, flashing covers up the weak spots we mentioned above. For example, take a typical gable roof—the standard triangular style you find on most homes—but on a small structure like a garage or garden shed.

The peak of that triangular structure is one such weak point since the area where the two slopes meet creates a tiny valley that water can settle in. Even the slightest imperfection in the way the roof is built would provide an opening for that water to seep into the building itself, and with enough time, there wouldn’t even need to be an imperfection.

On a large structure like a house, this peak might be covered by ridge cap shingles, as they provide a more aesthetically pleasing finish. But on something smaller, or something where the looks are not as important, flashing would be used.

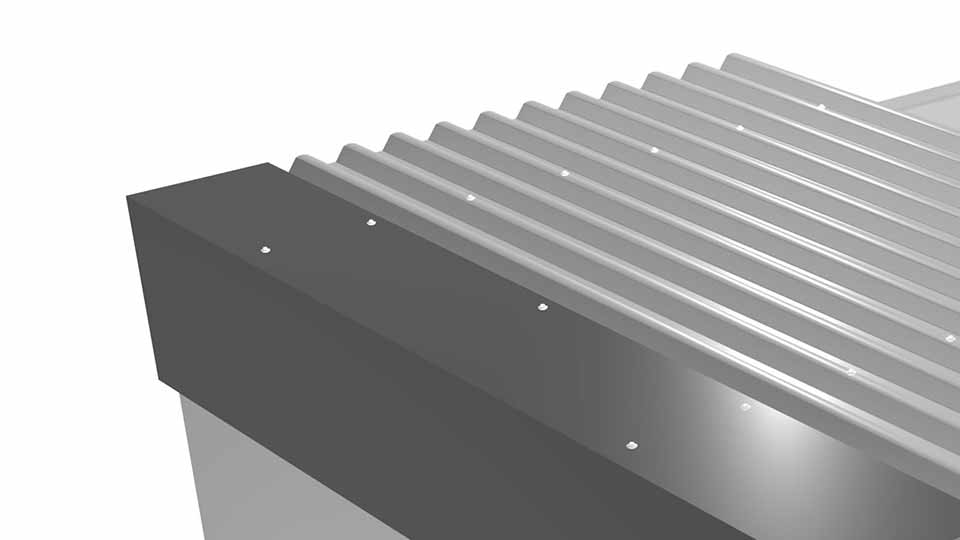

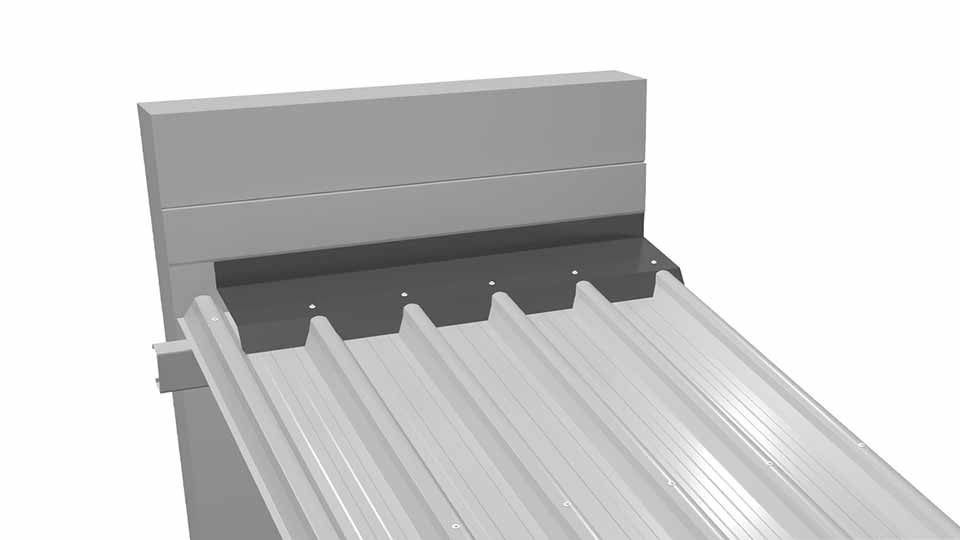

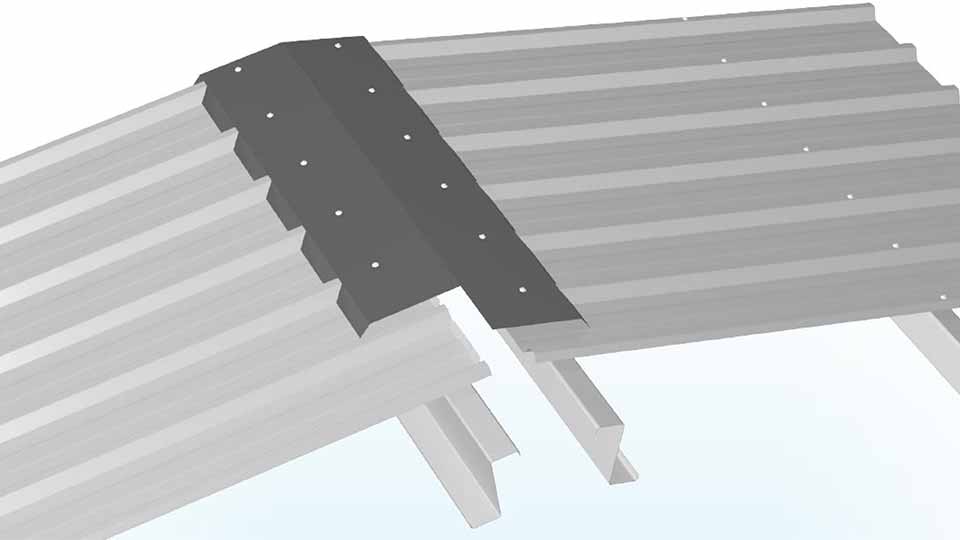

This would take the form of a strip of metal that is laid along the length of the roof peak and folded to follow the profile of the roof. The peak would then be protected by the flashing, with any water that hits it merely rolling harmlessly down the sides and onto the roof proper, where it would roll down to the edge as intended.

For a junction where a section of the roof meets a vertical surface, such as you might find with the roof of an extension mating up to the wall of the building it is an extension of or the area around a chimney, the basic premise would be the same. But this time the flashing would be folding the opposite way, making a kind of “L” shape against the wall and the roof, protecting that weak spot where they meet.

What Materials Are Used When Flashing a Roof?

There is no specific material that needs to be used for flashing a roof. The desired qualities are that it is impermeable, resistant to erosion, and smooth so that water will easily roll off of it.

To that end, the materials typically used for flashing a roof include plastic and metals, as well as composite materials. Naturally, these materials need to be suitable for exposure to water, so the metals used cannot be metals that rust. Metals like copper, lead, stainless steel, and aluminium are the most commonly used for this purpose.

The exact material chosen for any given project is determined by many factors. For example, metal is typically the most durable option, meaning there will be a greater length of time before the flashing will need replacing or repairing. But metal is also the most expensive option, so budget constraints may result in plastic being the best option. Unfortunately, plastic wears down quicker than metal, especially when exposed to direct sunlight, as it would most likely be on the roof of a building.

Metal flashing is also popular due to it being malleable. Plastic flashing may be cheaper, but it does not bend easily, and so tends only to get used in situations where the area being flashed is simple, such as a square vent on a flat roof where all the interfaces are right angles. Malleable metals can be moulded into shape to suit whatever the lay of the land—or roof—is. This makes it ideal for those awkward spots since a roofer can turn up with a roll of flashing and mould it to fit.

Which Areas of a Roof Need Flashing?

There are several areas of a roof that would require flashing. As we’ve mentioned, the basic rule is that anywhere a roof interfaces with another surface will probably require flashing. That being said, it can’t hurt to outline precisely where these regions are.

Roof Peaks

We won’t dwell on this one as we already mentioned it above, but in short, for roofs that come to a peak, the top of that peak needs extra protection to prevent water from settling in the area where the two sides of the roof meet.

Chimneys

Chimneys can be one of the more awkward areas to flash since they can come in a variety of different shapes, sizes, and locations on the roof. Regardless of how they are on any given roof, the point where the roof meets up with the walls of the chimney need flashing in order to stop rainwater getting in and turning your chimney walls into a water feature!

Skylights

Skylights another awkward one, since they are essentially punching a hole in the roof. For this kind of situation, it is common to use a single piece of flashing that is designed to go with the skylight, so as to prevent issues at the points where the different sections of flashing meet.

Dormer

A dormer is a structural element that sticks out of a sloping roof. This could be a window bay or an entire extension to create livable space in the attic. Regardless of why the dormer is there, it needs flashing around the borders it creates with the existing roof.

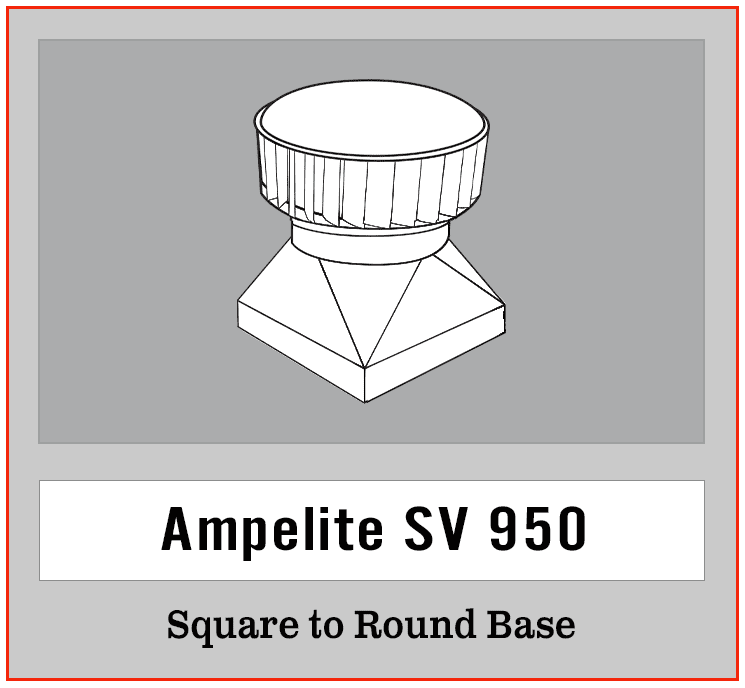

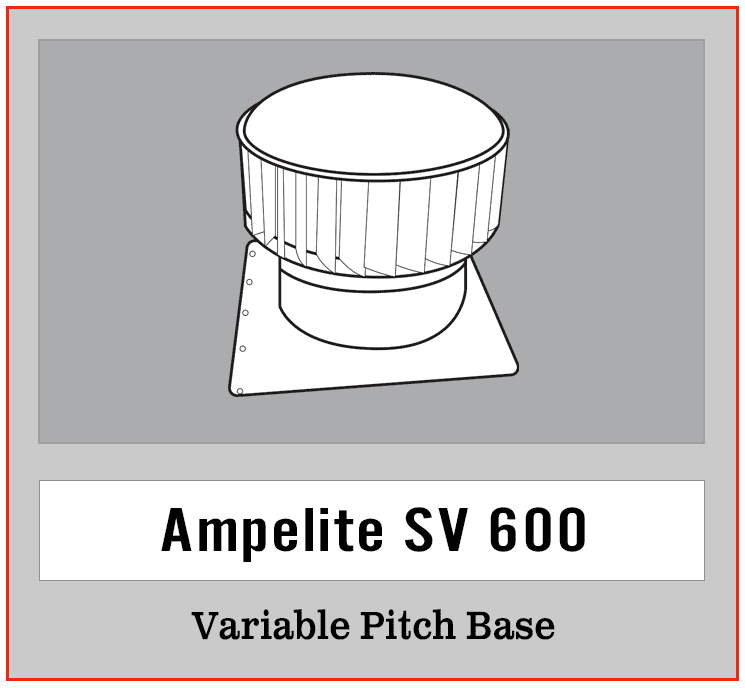

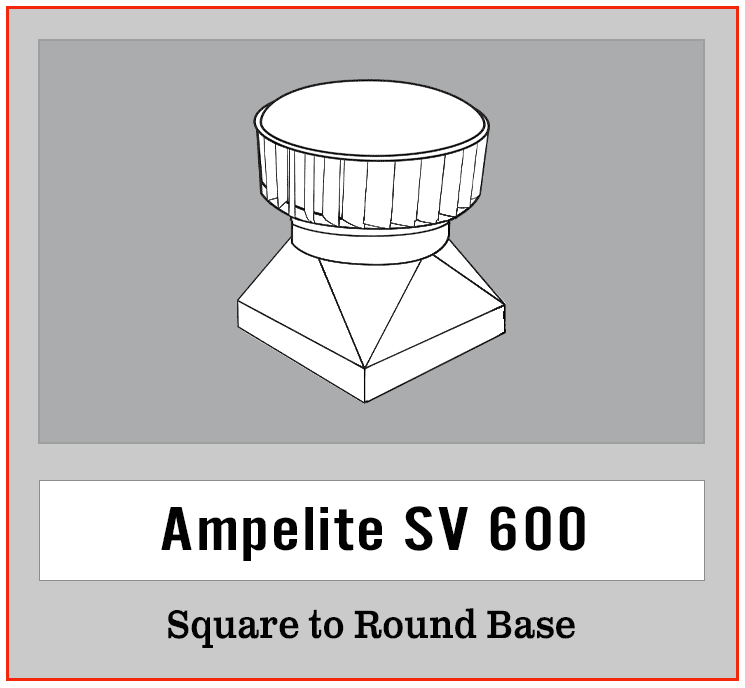

Roof Vents

It shouldn’t be a surprise that roof vents need flashing, since they are, from the perspective of the roof, like little chimneys. There are types of vents that would not need flashing, such as ridge vents, which would act as the shelter for the ridge of the roof themselves. And eaves vents, which are underneath the overhang of the roof, and sheltered from the rain.

For most roof vents, however, flashing is necessary as they are essentially pipes sticking up through the roof. Most vents will come with flashing that is designed to fit that particular vent and will be in one piece.

Maintenance

Given the nature of flashing, it is important to keep up with maintenance to ensure water does not start seeping into your property. Water can cause significant damage to the interior of a property. And, given the way buildings are constructed, and the places where flashing is commonly used, it is entirely possible—even likely—that any water ingress occurring around flashing would end up inside the structure of the building, invisible to the inhabitants.

This will likely result in a lot of damage being done before you are even aware there is a problem to fix. For example, water getting into the cavity inside your walls will not immediately show up as damp inside the building, but it will be causing problems with your insulation long before that happens.

Theft

An unfortunate reality of the modern world is that flashing often presents an easy target for thieves looking to make money on scrap metal. Some metals—particularly copper and lead—can be worth a considerable amount relative to other metals, and so some thieves make an effort to take any flashing that is reasonably easy to get to.

Granted, there are not many instances of thieves turning up at a two-story house with extendable ladders and stealing the flashing from the roof. But garages and low buildings or extensions are prime candidates for this kind of unsavoury behaviour. If you live in an area where this kind of thing happens, it may be worth considering one of the non-metal materials for your flashing.